-

Heat Treatment Services

-

Quality Control

- Safety

-

Company

Comprehensive Heat Treatment.

Zero

Compromise.

Analytic Stress delivers comprehensive heat treating

solutions with uncompromised quality, exceptional service, and innovative technology. Our

solutions are tailored to each customer’s specific needs.

350+

qualified

technicians

technicians

20

offices

45+

years in business

15

average years of

technician experience

technician experience

leaders in

Heat Treatment

SINCE 1979

50 States, 350+ qualified technicians

Analytic Stress is committed to being your trusted partner in heat treatment, delivering outstanding performance through industry-leading safety, quality, technology, and unmatched resources—all at the best value.

FULL SPECTRUM OF HEAT TREATING SERVICES

INNOVATIVE WIRELESS TECHNOLOGY

NATIONWIDE NETWORK

EXTENSIVE SAFETY PROGRAMS

HEAT TREATMENT

METHODS

At Analytic Stress, we work with you to

determine the best method for your application and are equipped to incorporate each method

with no outsourcing and with the highest level of experience in the industry.

ELECTRICAL RESISTANCE

Flexible Ceramic Pads (FCPs) may be the most

recognizable and precise method of heat treatment in our industry.

COMBUSTION

Portable systems offer versatility and accurate

temperature control in all areas within a massive volume of space.

INDUCTION

Portable induction units, self-contained water-cooling

systems, and remote data acquisition systems deployable worldwide.

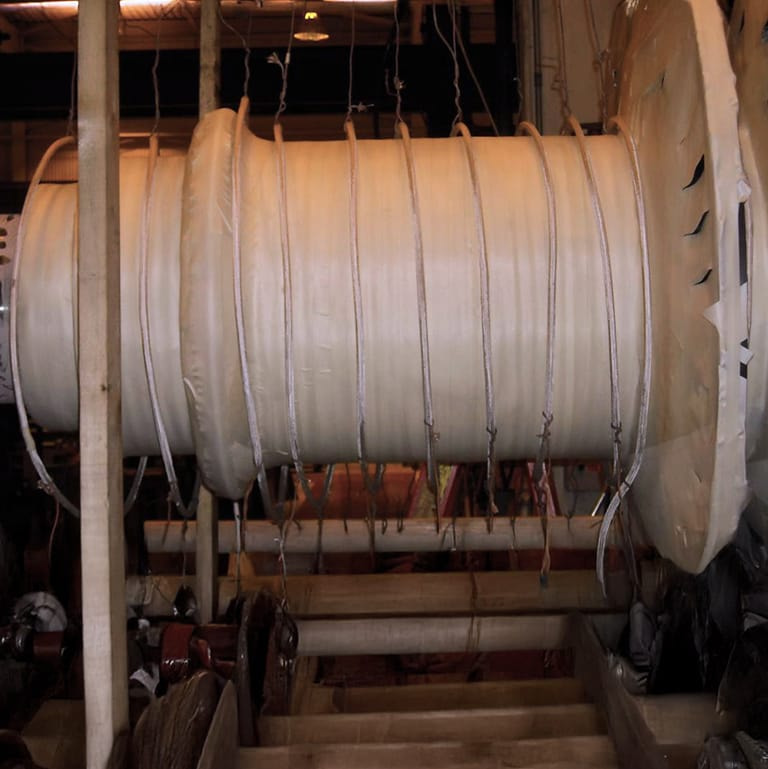

FURNACE

The Gulf Coast’s largest fleet of fixed-base furnaces

featuring a unique rail-mounted design and API-compliant quality assurance.

Why choose Analytic Stress?

With Analytic Stress, you know you're getting decades of experience and

uncompromising performance.