JOHN LINDSAY

Executive Director Of Safety And Risk Management

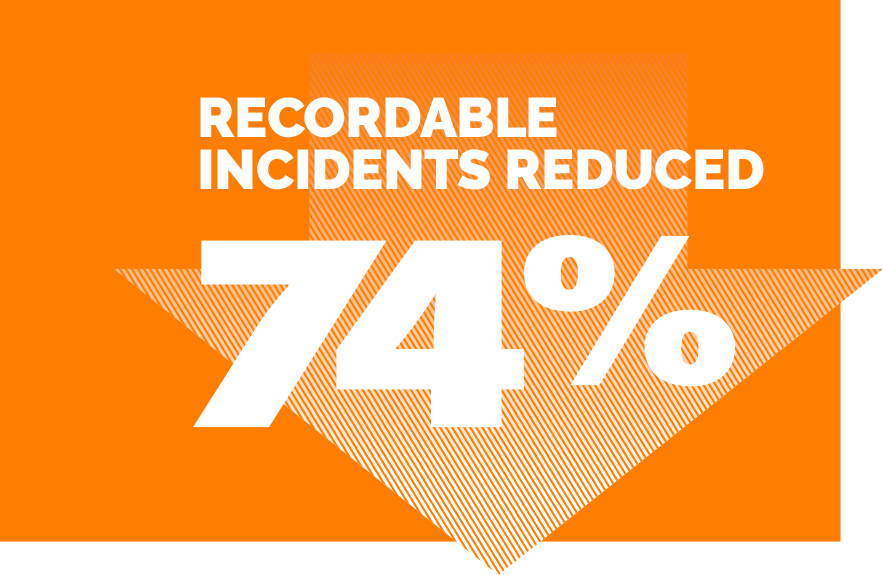

Based in La Porte, Texas, John Lindsay serves as ASRI’s Executive Director of Safety and Risk Management. John joined Analytic Stress Reliving Inc. in April 2014 after 10 years of experience in the oil and gas industry. Before his selection as Executive Director of Safety and Risk Management, John was a Plant Safety Manager for a Biodiesel refinery, a Safety Consultant for a Chemical Process Plant, and a Safety Manager for a Business Service. Under his leadership, John has been recognized and commended for developing safety, training, and behavioral-based safety programs. John is primarily responsible for the overall safety management of the company, which employs approximately 400 team members in 13 locations across the United States.

John earned his A.A.S from Columbia Southern University in Occupational Health and Safety and is currently working towards his B.A.A.S at Texas A & M-Commerce. John graduated from Texas A & M Engineering Extension Service as a Certified Safety and Health Official in General Industry and Construction. John also obtained his OSHA-authorized outreach trainer for General Industry and Construction from Texas A & M Engineering Extension Services. John has a strong investigative background with fourteen years in law enforcement and currently is an Advance TapRoot Team Lead investigator. John’s coursework involved Fundamentals of Occupational Safety and Health, Legal Aspects of Safety and Health, Industrial Ergonomics, OSHA Standards, Construction Safety, Interactions of Hazardous Materials, Business Communications, Training and Development, Introduction to Safety Studies, and Measure of Safety Performance. John also has certifications in Hazmat, D.O.T Compliance, Interview and Investigations, Report Writing, and Communications/Intervention/Coaching.